Hemp Building Materials Hold Their Own at Greenbuild in Los Angeles

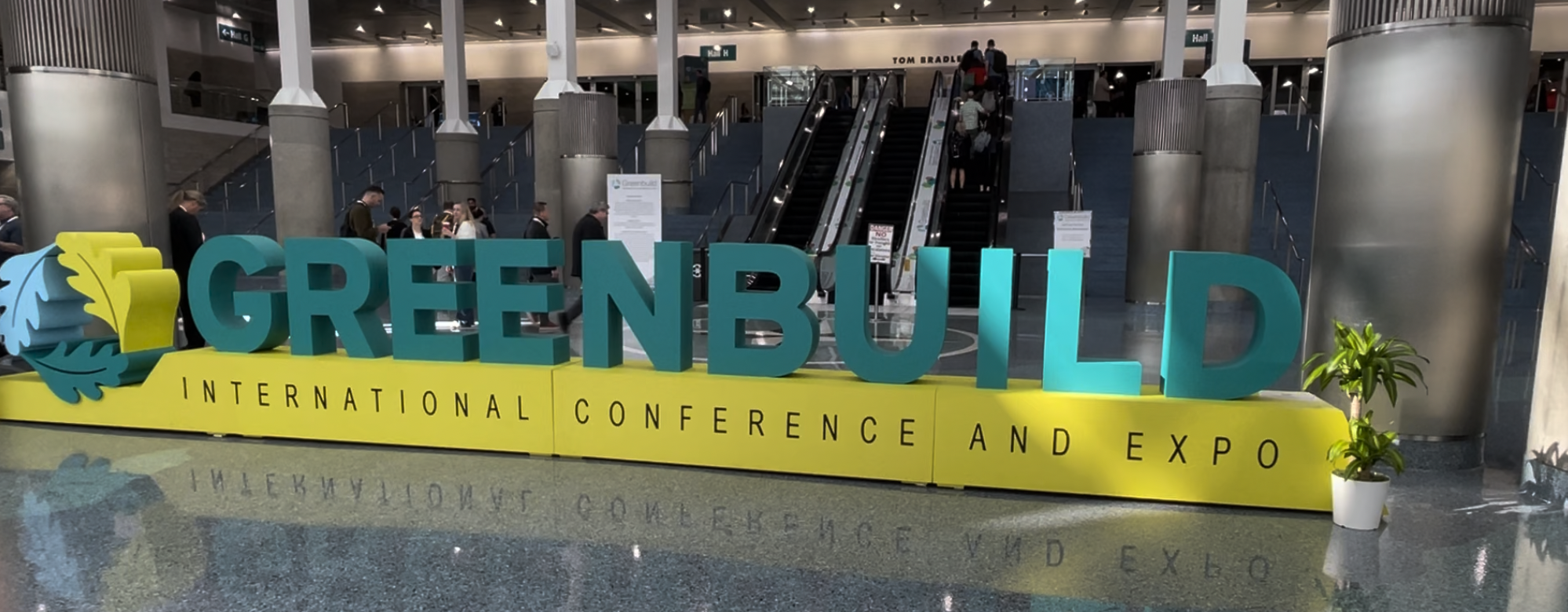

More than a dozen hemp-based building materials companies and specialists participated in the GreenBuild Expo at the Los Angeles Convention Center Nov. 4-7. Photo courtesy of Jean Lotus

Hemp Building Materials Hold Their Own at Greenbuild in Los Angeles

By Jean Lotus

At this year’s Greenbuild Conference and Expo, held Nov. 4–7 in Los Angeles, bio-based building materials took the spotlight — both on the show floor and in one of the conference’s most crowded sessions. As sustainability standards evolve, architects and builders are taking a serious look at hemp along with straw and other plant-based materials not just for their carbon benefits, but also for their non-toxic qualities and fire resistance, increasingly crucial in wildfire-prone California.

Greenbuild — the world’s largest annual event for green building professionals — draws thousands of attendees from architecture, engineering and construction fields, including more than 5,000 architects each year. With the rollout of LEED v5, the newest version of the U.S. Green Building Council’s certification system, biomass-based and mineral building materials are gaining fresh attention as essential tools for meeting embodied carbon goals.

A Well-Attended Conversation on the Bio-Based Future

One of the most talked-about sessions was a bio-based building materials panel, featuring Anthony Dente (Verdant Structural Engineers), Cameron McIntosh (Americhanvre), Lindsay Baker (International Living Future Institute) and Massey Burke (California Straw Building Association). The panel was well-attended, reflecting a surge of professional curiosity about materials once seen as niche.

McIntosh emphasized that materials like hemp, straw, and rice hulls are “rapidly, agriculturally renewable,” not horticultural crops (cannabinoid hemp) grown for flowers or oils. “What makes [industrial] hemp cool is that it’s a true agricultural commodity crop,” he said, noting its power to “bridge the divide between rural and urban America.” He added, “Support for American agriculture and increased domestic self-reliance... can begin to help heal that divide. We can talk to both sides.”

Bio-based construction advocates speak at a well-attended panel at GreenBuild Conference in Losa Angeles Nov. 6. (L-R) Massey Burke, California Straw Building Association, Anthony Dente, Verdant Structural Engineers, Lindsay Baker, Living Future and Cameron McIntosh, Americhanvre Cast Hemp. Photo courtesy of Jean Lotus

From Codes to Construction: New Technical Support

A clear theme at this year’s GreenBuild was the professionalization of bio-based materials, driven by technical testing and new building code pathways.

“At Verdant Structural Engineers, going on 20 years ago, we just wanted to help people get permits for what we considered to be the good stuff,” said Anthony Dente, whose firm led engineering work on the hemp-lime, straw bale, cob and light-straw clay appendices in the International Residential Code (IRC). “Now we have this set of tools that are helping us day in and day out, submitting for permits with what still is and used to be ‘alternative’ systems,” Dente added.

Dente explained that it’s now harder to get appendices adopted at the state and local level than to get them included in the national code. “It’s much more difficult to get a state to adopt an appendix than it is to get an appendix put into the international code,” he said, issuing a call-to-action for professionals to work locally to get hemp-lime and other bio-based building codes recognized locally.

Recent wins include adoption of the hemp-lime appendix by the City of Austin, Texas, and the State of Minnesota — important footholds that make permitting smoother for future projects.

On the Expo Floor: A Wide Selection of Hemp-Based Products

Greenbuild’s exhibition floor featured around a dozen companies showcasing the latest generation of hemp-based and plant-based building systems — from prefabricated panels to erosion control mats.

Connor Liles of Wittenberg, WI-based Sativa Building Systems presented his firm’s ICC-approved wall system, a hemp-lime panel designed to do away with the need for OSB sheathing and drywall. “It’s super mold resistant, super fire resistant,” Liles said. “People here in California are asking about wildfires... I think that’s going to be a great area for this.”

Scott Holmes of CA-based Hemp Cement Co. unveiled lightweight, Portland-free blocks and pavers. “It’s a one-to-one replacement,” Holmes said. “Forty percent lighter, no Portland cement, no lime, no clinker — and it does a better job.” Hemp Cement is the first company to license the patented hemp load-bearing block technology developed by University of Nebraska-Lincoln engineering professor Marc Maguire and Global Fiber Processing.

Ellie Fox of Kimball, MN-based Green Fox Companies introduced new acoustic and insulation panels, both Class A fire-rated. “The fire rating is what everyone’s asking about,” Fox told HempBuild Mag. “Especially here in wildfire zones.”

From Montana-based IND HEMP, Gregg Gnecco showcased an all-natural erosion control mat made with hemp fiber. “Most people don’t realize that slope stabilization mats are plastic,” he said. “We’re really excited that hemp can not only build your house, but give you all-natural site prep as well.”

Derek Wolf of Colorado-based Hemp and Block displayed load-bearing hempcrete and “hemp ICF” systems designed to eliminate wood from walls. “We were founded to make American-made, American-sourced materials,” Wolf said. “We need to be working with and supporting American farmers... to have economic sustainability,” he added.

Miles Gathright of New Smyrna Beach, FL-based Boardwurks brought composite boards made from hemp, sugarcane, elephant grass — and even recycled wind turbine blades and discarded boats. “We’re getting questions about where can we buy these, but we’re still just a start up,” he told HempBuild Mag.

Some of the Greenbuild attendees were veterans of multiple Greenbuild trade shows, including booth partners Greg Wilson of Murray, KY-based HempWood, and Mattie Mead of Idaho-based Hempitecture, Inc. Wilson said Greenbuild was usually his most successful trade show of the year. He showed off a new standing desk, developed after installing flooring at a series of Apple stores.

“When the economy's not strong, people are more apt to doing, say, a $500 or $1000 piece of furniture rather than a $20,000 flooring job,” he noted.

Mead of Hempitecture proudly showed off the company’s newest innovation, a fully flame-resistant version of Plant Panel X, a rigid continuous insulation panel that can be plastered and replace drywall.

Samantha Marino of Bismarck, ND-based Homeland Hempcrete described how her firm’s prefabricated “SHIPs” (Structural Hemp Insulated Panels) can be assembled quickly even in winter. “We went from a walkout basement to a roof in four business days,” she said. “We meet the client where they’re at — whether that’s an architect with drawings or just someone with a dream.”

Lisa Sundberg of the Indigenous Habitat Institute (IHI) in Trinidad, CA displayed large-format French hempcrete panels being localized for U.S. production. “This is the benchmark for us,” she said, emphasizing the importance of proper binders and a four-hour fire rating in a state where “insurance companies have exited” due to wildfire risk. The IHI completed a panelized ADU in Eureka CA this year.

Toward a Regenerative Building Industry

Together, the exhibitors and panelists at Greenbuild 2025 illustrated a key shift: biogenic building materials are moving from alternative to essential. As Dente put it, “We’re rapidly learning from what came before and applying it to what comes next.”

For McIntosh, the broader mission is cultural as much as technical: “These materials are bipartisan. They unite urban and rural communities,” he said. “We can have our cake and eat it too — building healthier, more sustainable homes while strengthening American agriculture.”

Please Support Our Classified Advertisers

(To find out more about advertising CLICK HERE).

Publications

Hemp Building Directory 2025 - Guide to the International Hemp Building Industry

Hempsteads: Architectural details for hemp-lime construction, by Timothy Callahan

Architects/Design Pros/Engineers

Next Genesis Design brings natural materials into high-performance building systems and healthy homes. White Salmon, WA

Bio-based Engineering and Design at Crownjade Design & Engineering, Greeley,CO

Experienced Natural Building Engineering Services from Verdant Structural Engineers, CA

Green Builders

Build your hempcrete dream house in Austin, TX with Gradek Contracting and Design

High Desert Hemp Homes - Building with hemp in the Rocky Mountains

Experienced Natural Building Engineering Services from Verdant Structural Engineers, CA

Naturalia Construction, Colorado-based Sustainable Construction with Hemp

Design and build your hempcrete home in Colorado’s front range with Healthy Hemp Homes

Aaron Grail Construction, No. Cal: The intersection of art, design and performance

Hemp Building Research and Training

Hemp Build School online and IRL for Homeowners and Professionals

Follow the Hemp Casita to learn more about building with hemp.

Hemp Hurd (shivs)/Hemp Fiber/ Hemp Microfiber

CannaVision, Fort Worth, TX: Home of the Pulsewave Hemp Processor

Riverdale Hemp Gin producing hemp raw materials in the Central Valley (CA)

IND HEMP: Supporting Farm Families and Rural Communities with Natural Materials Processing

Aggricrete, TX, Natural Materials with Superior Sustainability

Hempcrete installers/Insulation subcontractors

Americhanvre Cast Hemp: Supplies, Equipment, Experienced Hempcrete Installation

Hemp Build Network: We Make Building with Hemp Possible, New Braunfels, TX

Hemp Building Company: Hempcrete installation, supplies Lafayette, CO

Hemp Batt Insulation/Supplies

Lime Binders, Plasters and Mineral Paints

US Heritage Group: Experienced Hemp Building Binder Suppliers

Hemp and Block, LLC- Hempcrete Binder

Earthaus specialty lime plasters for the health & beauty of authentic mineral finishes

Silacote Environmentally Safe Inorganic Paints (CA and Canada)

Machine Manufacturing Companies

Quadra Concrete robotics and specialty machines in France and Phoenix, AZ USA

Hemp Wall Panel Products

Preorder your hempcrete tiny house from Sativa Building Systems

Panel solutions from Homeland Hempcrete

Hemp Composite Boards

Bison Biocomposites produces sustainable thermal insulation, hempcrete, hemp hurd, and more.

Hemp Blocks