VA Board Votes to Adopt Hemp-Lime in Residential Building Codes

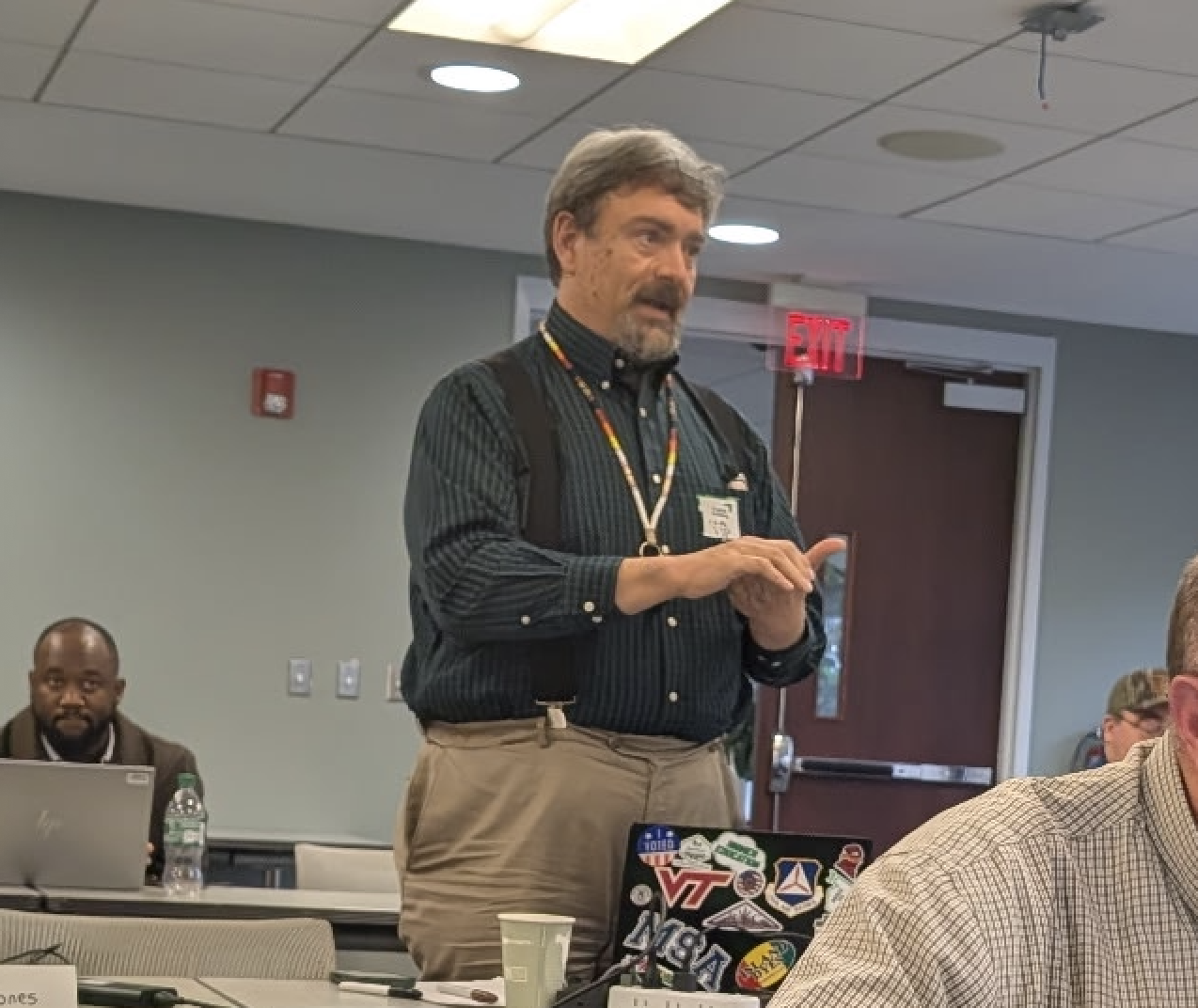

Virginia hemp-lime builder Scott McStacy testifies on behalf of IRC Appendix BL (Hempcrete Construction) at the Jan. 6 Board of Housing and Community Development’s General Stakeholder Workgroup Meeting in Glen Allen, VA

Editor’s note: Virginia-based hemp-lime builder Scott McStacy single-handedly submitted a proposal to adopt International Residential Code Appendix BL (Hemp-Lime “Hempcrete” Construction) into the Virginia Uniform Statewide Building Code – and on Jan. 6, McStacy appeared before the Board of Housing and Community Development’s General Stakeholder Workgroup Meeting in Glen Allen, VA and urged the board to adopt Appendix BL. The board voted unanimously in favor.

The Commonwealth of Virginia is now the third US jurisdiction (after the state of Minnesota and the city of Austin TX) that has moved forward with adopting Appendix BL into the local/state residential building codes.

What Hemp-Lime Taught Me About Building, Codes, and Persistence

By Scott McStasy

The first time you build with hemp-lime (often called hempcrete), you learn quickly that it is not just a material choice. It is a systems choice. It changes how you think about labor, sequencing, moisture, detailing, inspections, and, most of all, how you communicate a “new” technology inside an old framework that was not designed for it.

I learned that in the most direct way possible while building an off-grid hemp-lime home in Hardy, VA, an experience that tested me physically, challenged me professionally, and ultimately pushed me into Virginia’s code-development process. What started as a grueling 28-day build became something much bigger: a personal lesson in how innovation becomes “normal,” one inspector conversation and one public hearing at a time.

The Hardy Build: An Off-Grid Hemp-Lime Home in Franklin County

The Hardy house was modest in square footage, about 800 square feet, but it didn’t feel small. With 11-foot ceilings and an intentionally simple, off-grid design, it had the kind of volume and presence that makes you pause when you step inside. It was also a milestone: the first hemp-lime construction–based home in Franklin County, VA. From the outside, it looked like a small, well-proportioned structure. From the inside, from the perspective of the people mixing, moving, placing, tamping, and finishing, this house was a daily test of grit. We built it as a community workshop build, which adds a unique intensity. Workshops are powerful because you are building capacity in other people at the same time you are building a structure. But they also mean you’re constantly teaching while working, managing pace, answering questions, correcting technique, keeping momentum, and ensuring safety, day after day.

The Hardy House, built last summer in Franklin County, VA. Photo courtesy of Scott McStacy

And hemp-lime work is real work. It is repetitive, heavy, and demanding on the body: mixing, carrying, forming, compacting, and keeping the process moving like a heartbeat. If you lose rhythm, you lose time. I can say honestly: it was fulfilling in a way that is hard to describe. Hemp-lime has that effect on people. It feels like you’re doing something that makes sense, structurally, environmentally, and humanly.

Hemp-lime insulation’s high performance properties make it a superior building envelope. Photo courtesy of Scott McStacy

Why Hemp-Lime: The Building Performance That Keeps Me Coming Back

I’ve worked with hemp-lime long enough to appreciate that its value is not a single feature. It is the combination of properties that add up to a healthier, more resilient building envelope. When I talk about hemp-lime, I’m not selling a trend. I’m describing a performance profile that, in my view, directly addresses some of the biggest problems in modern construction:

Moisture and mold resistance: Hemp-lime assemblies can manage moisture in a way that reduces the conditions that allow mold to thrive.

Fire resistance: Properly designed and finished hemp-lime wall systems can deliver strong fire performance characteristics.

Pest resistance: Termites can’t “eat” a mineralized lime matrix, and pests generally don’t treat it like a food source or nesting material the way they do conventional assemblies.

Durability and comfort: The material’s hygrothermal behavior supports indoor comfort and stability in a way people can feel once they live in it.

Sustainability: The supply chain potential matters, especially in agricultural states, because hemp can become a viable row-crop input into local building materials.

That last point matters to me as much as anything. This isn’t just about houses. It’s about what rural communities can grow, process, and build with, locally. But performance alone does not make a technology “easy.” Codes do.

The Inspector Reality: When the Code Doesn’t Have Your Back

During the Hardy build, I had a realization that many innovators run into: if a system isn’t in the code, you are often navigating without a map. In theory, the inspection process is where you go for clarity, where the “how” is translated into enforceable, safe practice. In reality, when something is outside the written code, even good inspectors can be put in a difficult position. They may be reasonable, curious, and supportive, but they’re also working inside a framework that tells them what they can approve, what they can’t, and what they are accountable for. In Hardy, the inspector was great. He wasn’t hostile or dismissive. But it was clear that hemp-lime construction wasn’t something he had been trained on, and it wasn’t something the Virginia Residential Code (VRC) gave him clean guidance for at that time. That gap creates friction, not necessarily because people want to say “no,” but because uncertainty is expensive. Uncertainty creates delays. Uncertainty creates risk. Uncertainty creates inconsistent outcomes from one jurisdiction to another.

It also creates an obvious question:

If hemp-lime is going to scale, how do we make it legible inside the code?

The Deadline: Moving From Builder to Advocate

Fast forward to October 2025. I learned that the deadline was approaching for proposing changes to the Virginia Residential Code. Hemp-lime needed a clearer pathway, and the window to act was closing. So, I wrote a proposal to adopt Appendix BL (from the 2024 International Residential Code) into the Virginia code framework. The deadline was October 31. I submitted it on October 29. That submission wasn’t just paperwork. It was me deciding that, instead of complaining about the gap, I was going to try to close it.

And then came the part that separates good intentions from real commitment: showing up.

January 6, 2026: Eight Hours, 50th Place, and a Room Full of Questions

The public comment portion of the process was held on January 6, 2026, in Richmond. I drove three hours to get there. I waited over eight hours to present. I was 50th out of 51 proposals. That kind of wait does something to you. You have time to think. You have time to listen. You have time to watch how people make arguments, what types of objections show up, which details matter, and how policy language is actually evaluated in a room full of professionals.

Over the course of the day, I refined my approach. I clarified what I needed to say. I cut what didn’t serve the objective. Because my objective was simple:

Adopt Appendix BL into Virginia’s code so hemp-lime construction has a clear, standardized pathway.

When my turn finally came, I started at the beginning, not with jargon, but with a plain explanation of what hemp-lime construction is. I had to, because there were inspectors in the room who had never even heard of it. I explained the material. I explained why builders are using it. I discussed performance: sustainability, fire resistance, moisture behavior, mold resistance, pest resistance. I also gave context, pointing to long-lived lime-and-plant-fiber building traditions that have existed for centuries, to make the point that “new to us” doesn’t always mean “unproven as a concept.” Then I brought it back to the proposal: a straightforward code adoption, not an experimental carve-out.

And then the questions started.

The Turning Point: Thoughtful Questions and Unanimous Support

What I remember most is not one specific question, it’s the tone. The questions were thoughtful, inquisitive, and grounded in genuine due diligence. They weren’t “gotcha” questions. They were the kind of questions you want regulators to ask: clear, practical, and aimed at understanding how this works safely and consistently. Every comment I received was positive.

I answered what I could, directly. I also make sure to connect the dots beyond the walls of a single house: that this technology can create new opportunities for farmers, new local supply chains, and a real building material pathway that can serve rural economies, not just niche projects. When the administrator called for support, multiple people spoke up in favor. When he asked for opposition, there was none. The proposal moved forward to the next level for final approval with unanimous consent. After months of work, and after the long day, the long wait, and the long drive, those two words landed with weight.

Unanimous consent.

The Drive Home: Relief, Momentum, and What Comes Next

On the drive back, I felt elated. Not just “happy,” but relieved, the kind of relief you feel when you’ve been carrying something alone and suddenly realize it’s no longer just yours. I drove three hours home feeling like I was floating. Because in that moment, hemp-lime wasn’t just a material I believed in. It was a material that had been heard, respected, and supported by the people responsible for safeguarding building standards. That matters. It means the conversation is changing.

And it reminded me why I keep coming back to this work, even when it’s hard on the body, even when the process is slow, even when the system isn’t built for you yet:

If we want better buildings, healthier buildings, more resilient buildings, more sustainable buildings, we must be willing to build them and to do the unglamorous work of making them legible to the world.

Hemp-Lime Is the Material, but the Real Build Is the Pathway

The Hardy house taught me what hemp-lime can do as a building material. It also taught me what it means to build a pathway, through inspection uncertainty, code ambiguity, and the simple reality that most institutions don’t move until someone shows up, explains clearly, and stays in the room long enough to be heard. I remember standing at the microphone after eight hours of waiting, explaining hemp-lime to people who had never heard of it, answering questions one by one, and watching support rise in a room where I could have easily been dismissed.

That’s the work.

And for the first time in a long time, it feels like Virginia is ready to take the next step.

Scott McStacy is the founder of Seed to Structure, LLC, based in Forest, VA

Please Support Our Classified Advertisers

(To find out more about advertising CLICK HERE).

Publications

PRE SALE: Hemp Building Directory 2026 - Guide to the International Hemp Building Industry

Hempsteads: Architectural details for hemp-lime construction, by Timothy Callahan

Architects/Design Pros/Engineers

Next Genesis Design brings natural materials into high-performance building systems and healthy homes. White Salmon, WA

Bio-based Engineering and Design at Crownjade Design & Engineering, Greeley, CO

Experienced Natural Building Engineering Services from Verdant Structural Engineers, CA

Green Builders

Naturalia Construction, Colorado-based Sustainable Construction with Hemp

Design and build your hempcrete home in Colorado’s front range with Healthy Hemp Homes

Aaron Grail Construction, No. Cal: The intersection of art, design and performance

Evolve Construction: Providing healthy, sustainable, housing for future generations. Northern CO

Hemp Building Research and Training

Hemp Build School online and IRL for Homeowners and Professionals

Follow the Hemp Casita from Right Coast Hemp to learn more about building with hemp.

Hemp Hurd (shivs)/Hemp Fiber/ Hemp Microfiber

CannaVision, Fort Worth, TX: Home of the Pulsewave Hemp Processor

Riverdale Hemp Gin producing hemp raw materials in the Central Valley (CA)

IND HEMP: Supporting Farm Families and Rural Communities with Natural Materials Processing

E3 Agriculture: Texas plant-based materials for construction, industry, and agriculture.

East Coast Hemp Supply: Your source for hemp building materials in NC

Prairie Band Ag. Hemp Hurd Cultivating a future rooted in nature. Holton KS

Hempcrete installers/Insulation subcontractors

Americhanvre Cast Hemp: Supplies, Equipment, Experienced Hempcrete Installation

Hemp Build Network: We Make Building with Hemp Possible, New Braunfels, TX

Hemp Building Company: Hempcrete installation, supplies Lafayette, CO

Victura Hemp: Spray-applied hemp installation in New England

Hemp Batt Insulation/Supplies

Lime Binders, Plasters and Mineral Paints

US Heritage Group: Experienced Hemp Building Binder Suppliers

Hemp and Block, LLC- Hempcrete Binder

Earthaus specialty lime plasters for the health & beauty of authentic mineral finishes

Silacote Environmentally Safe Inorganic Paints (CA and Canada)

EcoStucco creates natural pigments for natural lime-based wall systems.

Machine Manufacturing Companies

Quadra Concrete robotics and specialty machines in France and Phoenix, AZ USA

Hemp Wall Panel Products

Preorder your hempcrete tiny house from Sativa Building Systems

Panel solutions from Homeland Hempcrete

Hemp Hardwood and Flooring:

Hemp Blocks