$1M Awarded to NY Hemp Materials Research Team

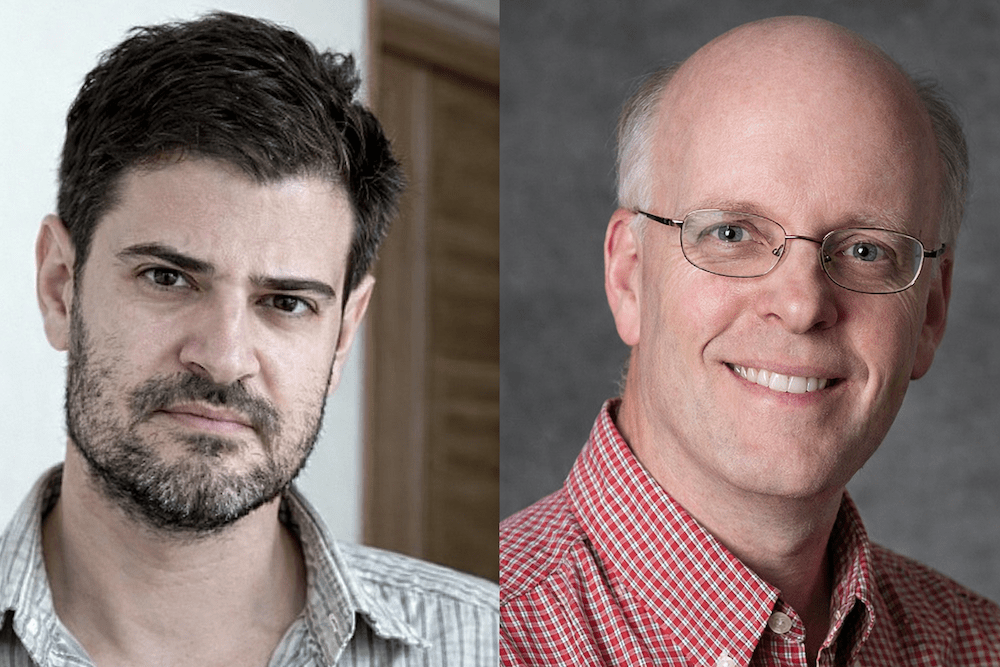

Alexander Tsamis speaks about the Seed to City initiative. Photo courtesy of Rensselaer Polytechnic University

By Jean Lotus

An industrial hemp research team at Rensselaer Polytechnic Institute (RPI) in Troy, New York has been awarded $1 million to build a state-funded manufacturing laboratory designed to bridge the gap between raw hemp fiber and the industrial market. Part of RPI’s Seed to City Initiative, the project is led by Dr. Alexandros Tsamis, Director of the Center for Architecture Science and Ecology (CASE), and Dr. Daniel Walczyk, Co-Director of the RPI New York Fashion Innovation Center. The project will follow a "commercialization-first" strategy to replace carbon-intensive synthetic products with natural alternatives.

"Seed to City is about turning plants into buildings," Tsamis said in a statement. “Right now, the construction industry is one of the biggest contributors to carbon emissions, and people are asking for cleaner, healthier, low‑carbon ways to build,” Tsamis explained. “But the supply chain for renewable materials doesn’t exist at scale yet. Seed to City is designed to fill that gap.”

The grant is part of a $5 million statewide grant from the state of New York and includes other educational institutions including Cornell University, Pratt and SUNY Morrisville and SUNY ESF.

“The idea is to establish a circular economy in the state around hemp,” Tsamis told HempBuild Mag.

Tsamis and Walczyk are part of a team that has been awarded other grants to develop prototyped building products from hemp including hemp rebar and hemp insulated siding.

Alexandros Tsamis, Director of the Center for Architecture Science and Ecology (CASE) (L), and Daniel Walczyk, Co-Director of the RPI New York Fashion Innovation Center (R). Photo courtesy of Rensselaer Polytechnic Institute

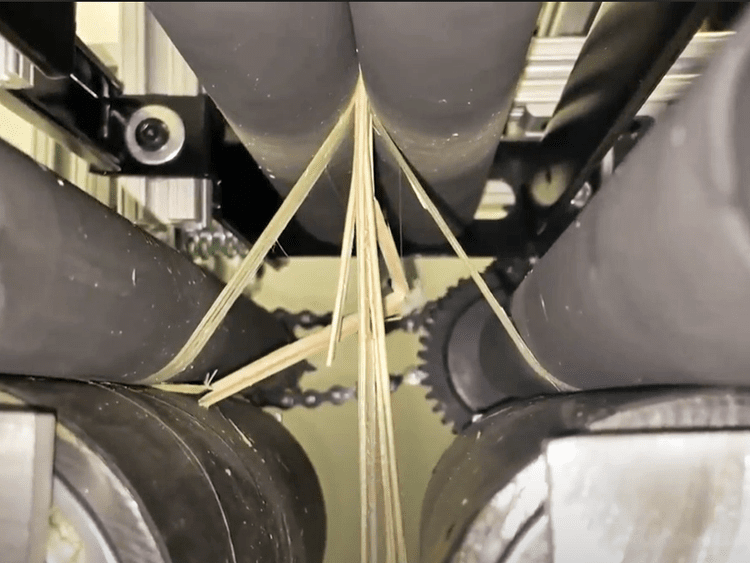

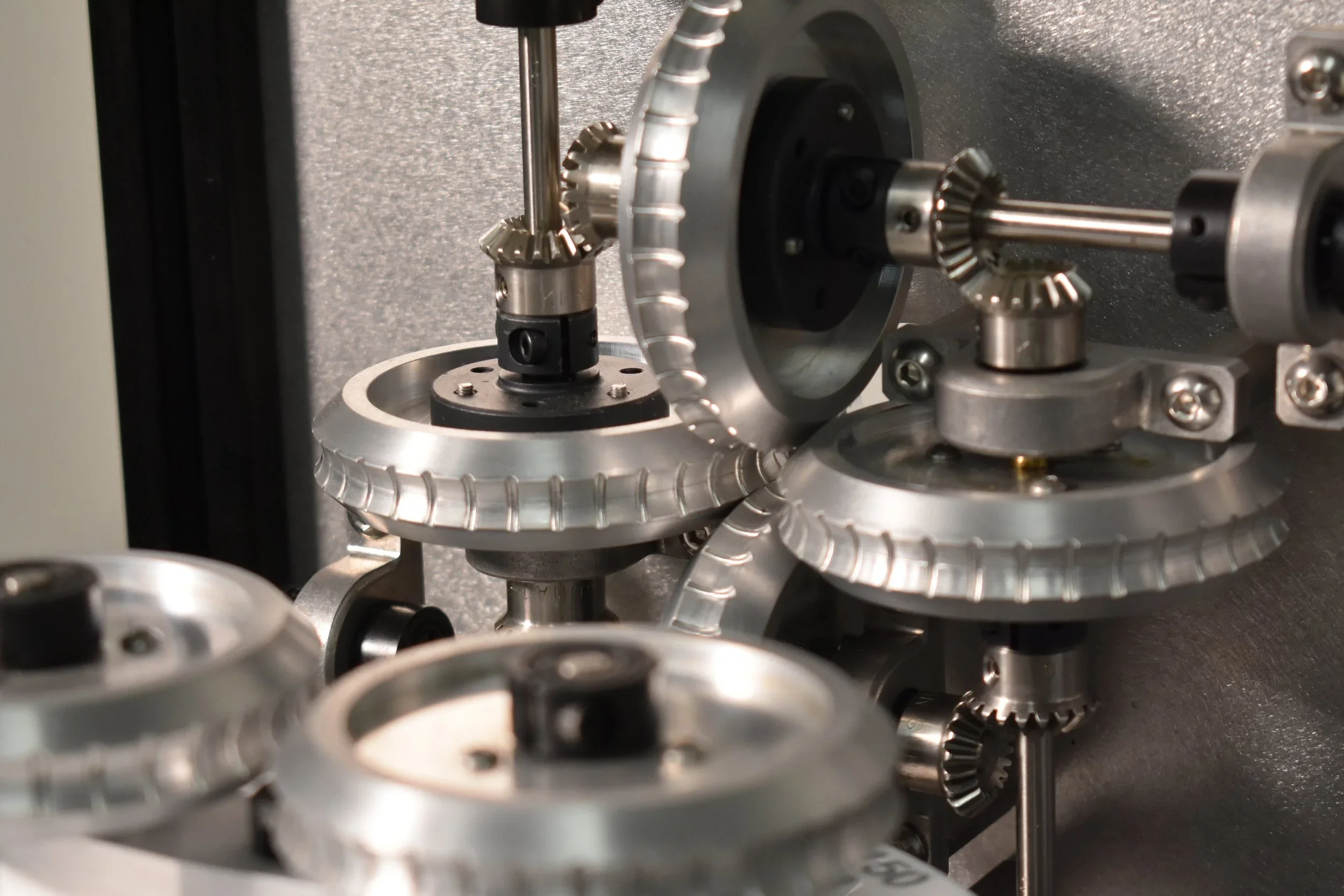

A machine is used to split hemp stalks into bast (outer bark) and hurd or shives (inner bark). Photo courtesy of Rensselaer Polytechnic Institute

The Strategy: Adapting the Industrial Standard

The core of the initiative is a practical approach to manufacturing: instead of developing entirely new, niche machinery, the team is equipping the lab with standard industrial equipment typically used for petroleum-based synthetics like fiberglass and carbon fiber. The goal is to modify these established systems to accept natural fibers.

"These are industrial scale machines, and they are actually used in industry for the synthetic material," Tsamis said. "So we are getting exactly the same equipment."

By focusing on making existing systems adaptable, the team aims to lower the barrier for traditional manufacturers to switch to bio-based inputs.

RPI’s CASE Team developed a hemp-based rebar. Photo courtesy of Rensselaer Polytechnic Institute

From Pultruders to Prepreggers

The lab’s $1 million equipment list includes heavy-duty machinery designed for high-volume production:

Pultruders: For creating continuous lengths of composite rebar, I-beams, and siding.

Pin Felters: Traditional textile equipment used to create non-woven mats and insulation.

Prepreggers: Machines that infuse fibers with resin to create ready-to-use composite sheets.

The research team will spend the coming months experimenting with these systems to find the precise configurations required for hemp. Walczyk noted that much of the work involves determining the correct settings and "dials" to ensure natural fibers behave predictably within these high-speed systems.

Industry Collaboration and Performance

Once the lab is operational, RPI plans to invite leaders from the textiles, nonwovens, and building materials sectors to witness these bio-based production lines. The focus remains on real-world performance and ensuring that hemp products can meet the rigorous thresholds required for mainstream adoption.

“There is some R&D involved in making the transition,” Tsamis told HempBuild Mag. “It's not as simple as flicking a switch and it happens. But it is not as difficult as other people imagine. And that's the purpose of the lab, is to have the equivalent equipment to what you can find industry and concentrate it, and then for companies to come and see how a transition can take place.”

A primary goal is to achieve high throughput. According to Tsamis, the industry needs to focus on manufacturing speed to keep costs competitive with synthetic materials. By proving that hemp can be processed on industrial-scale equipment, the team hopes to convince manufacturers that bio-based materials are a viable, scalable alternative to fiberglass and plastic.

Building a Circular Bioeconomy

The Seed to City initiative is an effort to establish a regional supply chain that connects New York farmers to urban architects and builders. By focusing on downstream manufacturing capability, the project aims to solve the industry’s biggest bottleneck: the lack of industrial-scale processing for renewable materials.

Industrial machinery that will be tweaked to process plant-based materials as quickly and cost efficiently as synthetic ones. Photo courtesy of Rensselaer Polytechnic Institute

“New York State is uniquely positioned to lead a circular bioeconomy around hemp,” Walczyk said, “with farmers ready to grow, universities advancing R&D, startups producing feedstocks and products, and the nation’s largest concentration of architects and builders.”

Please Support Our Classified Advertisers

(To find out more about advertising CLICK HERE).

Publications

PRE SALE: Hemp Building Directory 2026 - Guide to the International Hemp Building Industry

Hempsteads: Architectural details for hemp-lime construction, by Timothy Callahan

Architects/Design Pros/Engineers

Next Genesis Design brings natural materials into high-performance building systems and healthy homes. White Salmon, WA

Bio-based Engineering and Design at Crownjade Design & Engineering, Greeley, CO

Experienced Natural Building Engineering Services from Verdant Structural Engineers, CA

Green Builders

Naturalia Construction, Colorado-based Sustainable Construction with Hemp

Design and build your hempcrete home in Colorado’s front range with Healthy Hemp Homes

Aaron Grail Construction, No. Cal: The intersection of art, design and performance

Evolve Construction: Providing healthy, sustainable, housing for future generations. Northern CO

Hemp Building Research and Training

Hemp Build School online and IRL for Homeowners and Professionals

Follow the Hemp Casita from Right Coast Hemp to learn more about building with hemp.

Hemp Hurd (shivs)/Hemp Fiber/ Hemp Microfiber

CannaVision, Fort Worth, TX: Home of the Pulsewave Hemp Processor

Riverdale Hemp Gin producing hemp raw materials in the Central Valley (CA)

IND HEMP: Supporting Farm Families and Rural Communities with Natural Materials Processing

E3 Agriculture: Texas plant-based materials for construction, industry, and agriculture.

East Coast Hemp Supply: Your source for hemp building materials in NC

Prairie Band Ag. Hemp Hurd Cultivating a future rooted in nature. Holton KS

Hempcrete installers/Insulation subcontractors

Americhanvre Cast Hemp: Supplies, Equipment, Experienced Hempcrete Installation

Hemp Build Network: We Make Building with Hemp Possible, New Braunfels, TX

Hemp Building Company: Hempcrete installation, supplies Lafayette, CO

Victura Hemp: Spray-applied hemp installation in New England

Hemp Batt Insulation/Supplies

Lime Binders, Plasters and Mineral Paints

US Heritage Group: Experienced Hemp Building Binder Suppliers

Hemp and Block, LLC- Hempcrete Binder

Earthaus specialty lime plasters for the health & beauty of authentic mineral finishes

Silacote Environmentally Safe Inorganic Paints (CA and Canada)

EcoStucco creates natural pigments for natural lime-based wall systems.

Machine Manufacturing Companies

Quadra Concrete robotics and specialty machines in France and Phoenix, AZ USA

Hemp Wall Panel Products

Preorder your hempcrete tiny house from Sativa Building Systems

Panel solutions from Homeland Hempcrete

Hemp Hardwood and Flooring:

Hemp Blocks