Renewabuild Revives Interlocking Hemp Block with Canada, US Factories

John Peterson of Wakonda, SD-based Dakota Hemp moves a skid of interlocking hempcrete blocks from Renewabuild. Photo courtesy Ken Meyer

By Jean Lotus

Ten years after the invention of a "Lego-style" interlocking hempcrete block captured the imagination of the hemp building world, the technology is making a comeback under a new name and a revamped business model.

Renewabuild, a sustainable building company based in Surrey, BC, has built a facility licensing the intellectual property of Canadian company Just BioFiber (JBF). The company’s facility manufactures two blocks per minute, founders say. A South Dakota consortium led by John Peterson of Wakonda, SD-based Dakota Hemp will be the first U.S. entity to license the technology.

At a cost of about $50 USD per sq. foot, the updated system is designed to compete directly with traditional building methods like concrete masonry units (CMU) rather than just standard wood-frame construction, founder David Geertz, who led the development of the new regionalized business plan, told HempBuild Mag. By restructuring the business model from a centralized "mega factory" to a regionalized licensing approach, Renewabuild aims to make the technology more accessible to local markets across North America.

Geertz described the potential for hemp growers to become industrial suppliers for the construction sector. "Essentially what they're doing is they're growing aggregate out of the ground," Geertz said. "They're essentially a renewable gravel pit for a cement alternative."

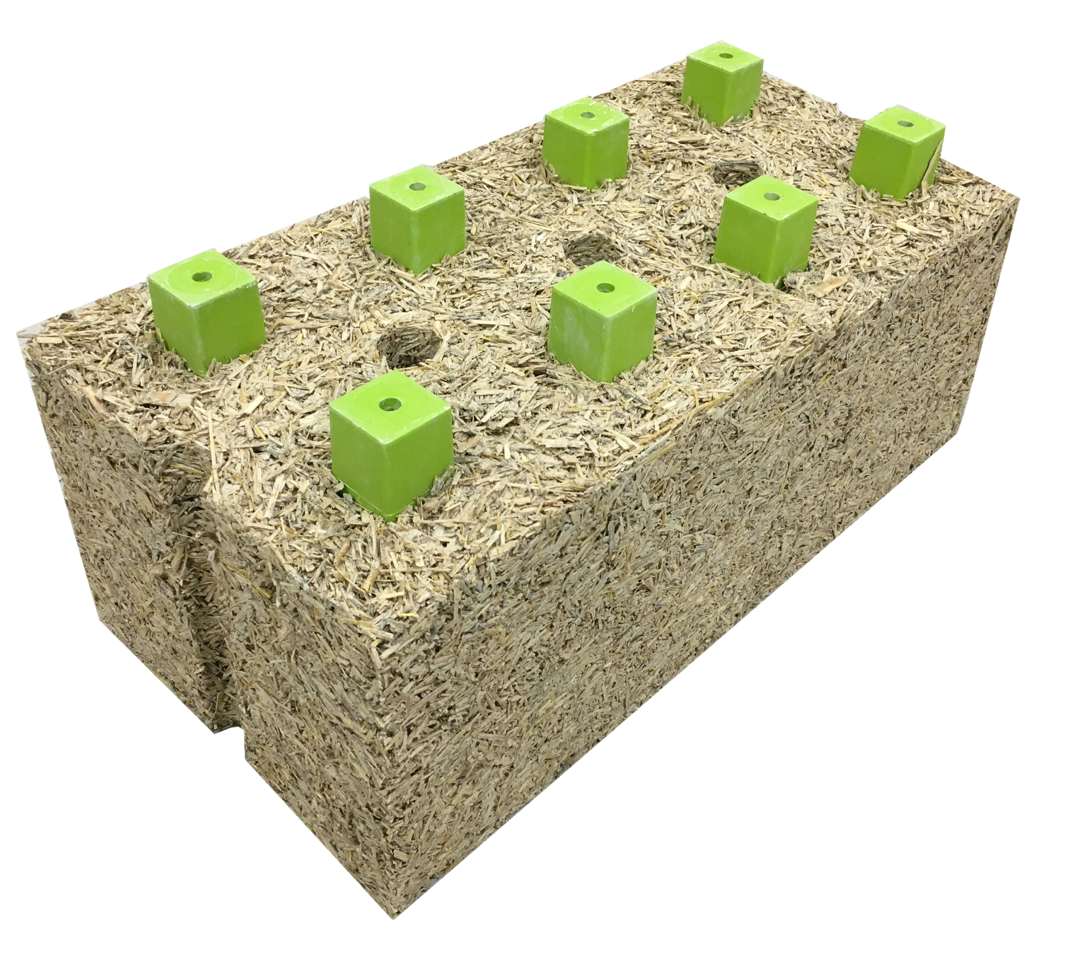

An interlocking hemp-lime brick. Photo courtesy of Renewabuild

For Terry Radford, President of Just BioFiber, the reintroduction follows nearly a decade of development and overcoming the logistical hurdles posed by the global pandemic. "My concern is getting the blocks into the market because time ticks away," Radford told HempBuild Magazine. "I already don't care who manufactures blocks as long as they meet the quality requirements and they get into the market."

"Our goal was to provide a system that was cost-effective enough to get them whole in under one year on their investment," Geertz said, referring to potential licensees. He described the Surrey location, an hour east of Vancouver, as a strategic "light industrial kind of agrarian kind of area" ideal for the intersection of agriculture and construction.

‘Harmless Home’ shows off JBF technology

Nanaimo, BC-based architect Jaque “Jack” Anderson worked with the Just BioFiber blocks on one of the company’s largest builds, the so-called “Harmless Home” built on Vancouver Island, BC between 2017 and 2018 for client Arno Keinonen.

Anderson praised the interlocking block system and engineered tension rods that made the project go together.

“The system works so well together,” Anderson told HempBuild Mag. “One of the things that really excites me is thermal mass, and I know there are sensors in the walls of the Harmless Home that prove it actually performs better thermally in the summertime to keep the heat out than they thought.”

First U.S. License in South Dakota

The expansion into the United States is being led by a consortium in South Dakota, marking the first time the JBF technology will be manufactured outside of Canada. John Peterson of Dakota Hemp confirmed that his group has secured the necessary investment for the licensing down payment.

The South Dakota group expects to have its production line operational by late Q2 of 2026, Peterson told HempBuild Mag.

Advancements in Manufacturing and Performance

The blocks consist of a rigid plastic frame encased in a hemp-lime mixture. Previously, JBF used compression molding to create these frames—a process that proved too slow for mass production.

"Compression molding was taking six minutes per product," Geertz explained. By switching to injection molding, the company has drastically increased speed and reduced costs.

The switch in polymers also improved the block's performance. "One of the big things about the new polymer is [it is] actually a little more flexible," Terry Radford noted, adding that this flexibility allows the system to "exceed all the earthquake requirements."

A technician moves a hemp-block from the factory line at Renewabuild in Surrey, BC. Photo courtesy of Renewabuild

Material Science and Future Expansion

The blocks utilize a binder mix of hydraulic lime and metakaolin (a pozzolan that increases strength and speeds up curing), notably avoiding Portland cement. While hemp is the primary aggregate, the company is also exploring other fibers. Geertz mentioned potential future tests with "wood waste" and other regional fibers like abaca and kenaf to adapt to different local supply chains.

Working with the building designer, the blocks are pre-engineered for load and are sold in a “kit” that fits the desired design. Currently, the Renewabuild factory in British Columbia, has stockpiled "10,000 molds and 10,000 frames ready to go," according to Geertz.

The Renewabuild facility in Surrey and the upcoming South Dakota plant represent the first steps in a broader strategy to establish regional hemp block factories near hemp processing hubs, Geertz said. By providing a "turnkey" manufacturing system, the companies hope to build a reliable supply chain that benefits both farmers and developers.

"It's the only way that the industry and the hemp build space is going to scale is by having that relationship with the builders who are critical in an ownership position," Geertz said.

Please Support Our Classified Advertisers

(To find out more about advertising CLICK HERE).

Publications

PRE SALE: Hemp Building Directory 2026 - Guide to the International Hemp Building Industry

Hempsteads: Architectural details for hemp-lime construction, by Timothy Callahan

Architects/Design Pros/Engineers

Next Genesis Design brings natural materials into high-performance building systems and healthy homes. White Salmon, WA

Bio-based Engineering and Design at Crownjade Design & Engineering, Greeley, CO

Experienced Natural Building Engineering Services from Verdant Structural Engineers, CA

Green Builders

Naturalia Construction, Colorado-based Sustainable Construction with Hemp

Design and build your hempcrete home in Colorado’s front range with Healthy Hemp Homes

Aaron Grail Construction, No. Cal: The intersection of art, design and performance

Evolve Construction: Providing healthy, sustainable, housing for future generations. Northern CO

Hemp Building Research and Training

Hemp Build School online and IRL for Homeowners and Professionals

Follow the Hemp Casita from Right Coast Hemp to learn more about building with hemp.

Hemp Hurd (shivs)/Hemp Fiber/ Hemp Microfiber

CannaVision, Fort Worth, TX: Home of the Pulsewave Hemp Processor

Riverdale Hemp Gin producing hemp raw materials in the Central Valley (CA)

IND HEMP: Supporting Farm Families and Rural Communities with Natural Materials Processing

E3 Agriculture: Texas plant-based materials for construction, industry, and agriculture.

East Coast Hemp Supply: Your source for hemp building materials in NC

Prairie Band Ag. Hemp Hurd Cultivating a future rooted in nature. Holton KS

Hempcrete installers/Insulation subcontractors

Americhanvre Cast Hemp: Supplies, Equipment, Experienced Hempcrete Installation

Hemp Build Network: We Make Building with Hemp Possible, New Braunfels, TX

Hemp Building Company: Hempcrete installation, supplies Lafayette, CO

Victura Hemp: Spray-applied hemp installation in New England

Hemp Batt Insulation/Supplies

Lime Binders, Plasters and Mineral Paints

US Heritage Group: Experienced Hemp Building Binder Suppliers

Hemp and Block, LLC- Hempcrete Binder

Earthaus specialty lime plasters for the health & beauty of authentic mineral finishes

Silacote Environmentally Safe Inorganic Paints (CA and Canada)

EcoStucco creates natural pigments for natural lime-based wall systems.

Magic Minerals hemp-lime catalyst: Proven success. Made in USA

Machine Manufacturing Companies

Quadra Concrete robotics and specialty machines in France and Phoenix, AZ USA

Hemp Wall Panel Products

Preorder your hempcrete tiny house from Sativa Building Systems

Panel solutions from Homeland Hempcrete

Hemp Hardwood and Flooring:

Hemp Blocks